Metal Therapy: How Collision Repair Restores More Than Cars

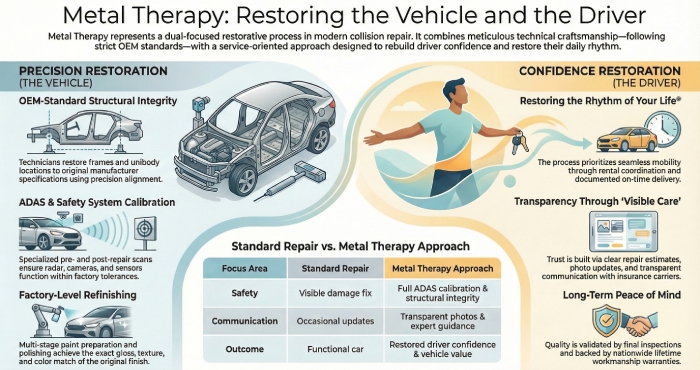

When a vehicle arrives at a collision repair facility, the services rendered typically extend beyond merely fixing dents and scratches. Some experts refer to this extensive restorative process as “metal therapy.” This term encompasses the meticulous repairs, reshaping, and refinishing that not only return the car to its former appearance but also help restore the owner’s confidence and sense of security.

By conducting thorough evaluations and applying expert skill and detailed craftsmanship, collision repair transcends simple repairs; it represents a rejuvenation that reestablishes the connection between individuals and the comfort, safety, and pride their vehicles embody.

Why “Metal Therapy” Matters in Modern Collision Care

True metal therapy is more than fixing sheet metal; it’s the thoughtful combination of collision repair and auto body repair practices that return people, not just vehicles, to a steady rhythm. From structural straightening to glass repair, paintless dent repair, and precise glass replacement, a capable auto body shop follows vehicle manufacturer repair guidelines to restore pre-accident condition and peace of mind.When the repair process is guided by OEM certifications, technician training, and quality assurance, the result is a safer vehicle repair and a calmer driver supported by clear communication with the insurance carrier and on-time delivery.

Rebuilding Driver Confidence After a Collision

Confidence begins with clarity. A skilled service advisor explains the repair estimate, outlines the repair process, and offers a free estimate when appropriate. They set expectations for disassembly, parts sourcing per vehicle manufacturer standards, and vehicle reassembly, while coordinating a rental car through partners like Enterprise so daily life continues.

Trust grows through visible care: photo updates, transparent insurer communications, and a final quality inspection before keys are returned. Many reputable auto body shop networks, such as Caliber Collision, back workmanship with a nationwide lifetime warranty designed to uphold pre-accident conditions. Their mission Restoring the Rhythm of Your Life® reflects how thoughtful collision repair and auto body repair serve both the vehicle and the person behind the wheel.

Safety Systems and Restoring Daily Mobility

1. Structural Integrity Comes First

Effective vehicle repair hinges on accurate structural alignment. Technicians meticulously take apart and assess frames and unibody locations, fixing or replacing parts to original equipment manufacturer (OEM) specifications. Limited use of filler and careful smoothing techniques maintain structural integrity, while bonding agents, finishes, and seals adhere to the manufacturer’s recommendations.

Glass repair or replacement complies with AGSC standards to prevent crack propagation and ensure windshields in cars contribute to airbag deployment timing and the vehicle’s overall rigidity, which are vital for returning the car to its pre-accident state.

a. ADAS Calibration and System Diagnostics

Today’s collision repair must address radar, cameras, and sensors. Pre- and post-repair scans, calibrations, and road tests often supported by specialists like Protech verify that ADAS functions align with vehicle manufacturer tolerances. I-CAR training and OEM certifications guide procedures for aiming cameras after glass replacement, bumper refinishing, or structural work, ensuring that safety systems perform as designed.

2. Returning Mobility, Reliably

Mobility is restored when the auto body repair journey is efficient. Solid scheduling, parts logistics, and on-time delivery minimize downtime, while Enterprise rental car support keeps life moving. Thorough vehicle reassembly and a documented quality assurance checklist ensure that everything panels, electronics, and glass functions as intended before the handoff back to the customer and the insurance carrier.

Preserving Vehicle Value Through Quality Repairs

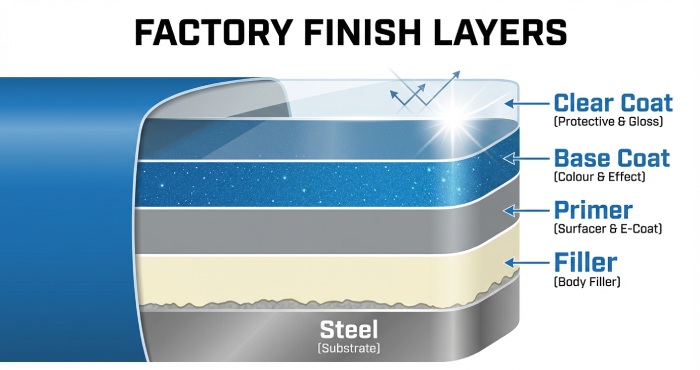

Matching Factory Finish and Materials

The value of a vehicle remains intact when its finish aligns with factory standards. Thorough paint preparation, involving abrasives and glazes, is essential for achieving a level surface before applying primers, sealers, and coatings to establish a strong foundation.

Precise shaping can be achieved using 3M™ Platinum™ body filler, while controlled smoothing is accomplished with 3M™ Cubitron™ II and Trizact™ products to ensure accurate contours.Paint is applied using 3M™ Accuspray™ ONE and PPS™ systems for uniformity and cleanliness, then enhanced with 3M™ Perfect-It™ compounds and polishes to achieve a high-gloss, deep finish the hallmark of top-tier collision repair.

a. Surface Preparation Essentials

- Abrasives selection controls heat and scratch depth

- Targeted glazes minimize rework before primer

- Sealers promote uniform color and adhesion for topcoats

b. Finish and Polishing Discipline

- Correct clear coat flash times prevent dieback

- Multi-stage compounding and polishing achieve OEM-level gloss

- A final quality inspection validates color match and texture

c. Dent Strategy That Protects Original Paint

Where feasible, paintless dent repair preserves factory vehicle paint, shortens cycle time, and can enhance resale value by avoiding refinish on original panels. Smart use of paintless dent repair limits filler usage, reduces material costs, and supports a cleaner environmental footprint all while meeting vehicle manufacturer expectations for pre-accident conditions.

Sustainability, OEM Identity, Community Trust, and Future-Proofing

Cutting Environmental Impact with Smart Repair Practices

Sustainable choices begin with accurate repair planning: use paintless dent repair when possible; prioritize glass repair before glass replacement to conserve materials; and right-size paint preparation to limit solvent use. Low-VOC paint coatings and efficient systems like 3M™ PPS™ reduce waste, while precise mixing and spray controls cut overspray and product consumption.

Materials and Waste Minimization

- Optimize adhesives and sealers usage to OEM-specified quantities

- Segregate abrasives, coatings, and solvents for responsible disposal

- Reduce rework through disciplined quality assurance gates

Matching OEM Fit and Finish to Protect Vehicle Identity

Authenticity matters. Adhering to vehicle manufacturer repair guidelines, selecting OEM parts where required, and performing accurate color-matching guard a vehicle’s identity and value. Details such as panel gap uniformity, texture consistency, and emblem placement reinforce pre-accident conditions. When glass replacement is necessary, AGSC practices and camera recalibration protect embedded technologies tied to the vehicle’s VIN and safety profile.

Fostering Community Trust and Safer Roads

Communities rely on collision repair to keep roads safe. Verified ADAS calibrations, documented test drives, and post-repair quality inspection protocols signal diligence. Public education explaining why a simple bumper repair may require sensor alignment builds trust. Shops that prioritize customer service, collaborate responsibly with the insurance carrier, and deliver on-time reinforce confidence that extends beyond the front counter.

Future-Proofing Repairs with Training and Diagnostics

As vehicles advance, so too must repair practices, requiring ongoing training, state-of-the-art diagnostics, and adherence to rigorous OEM-certified protocols. Repair shops that prioritize employee development, collaborations, and cutting-edge technologies such as ADAS calibration, advanced dent repair, and paintless dent repair are better equipped to provide safe and accurate service for today’s intricate automobiles.