Innovations In Collision Repair: How Technology Is Changing Auto Restoration

The automotive repair sector has progressed significantly from its roots in simple dent removal and body repairs. Nowadays, collision repair incorporates digital diagnostics, cutting-edge materials, and automation, resulting in quicker, more accurate, and budget-friendly outcomes. With the ongoing advancements in automotive technology, repair shops are adopting contemporary techniques that elevate vehicle restoration to a complex and refined operation.

The Shift Toward High-Tech Collision Repair

In the past, auto restoration relied heavily on skilled craftsmanship and a mechanic’s intuition. Today’s vehicles, however, feature advanced electronics, lightweight materials, and intricate safety systems that require precise, technology-driven repairs.

With sensors, cameras, and driver-assistance features, even small errors in alignment or calibration can compromise safety. To keep up, collision repair shops are investing in advanced tools and specialized training to ensure vehicles are restored accurately and reliably.

Digital Imaging and Damage Assessment

Intelligent Damage Assessment

Advanced imaging technologies powered by AI analyze vehicles to detect both apparent and concealed damages that conventional inspections could overlook. This enhances the precision in recognizing structural problems at an early stage.

Accelerated Insurance Processing

Detailed digital photographs can be rapidly transmitted to insurance providers, expediting the claims process. Additionally, machine learning applications can produce repair cost estimates in just a few minutes, streamlining the approval workflow.

Enhanced Precision and Efficiency

By minimizing uncertainty, AI solutions provide more accurate evaluations. This leads to quicker repair durations, ensuring convenience and reassurance for car owners.

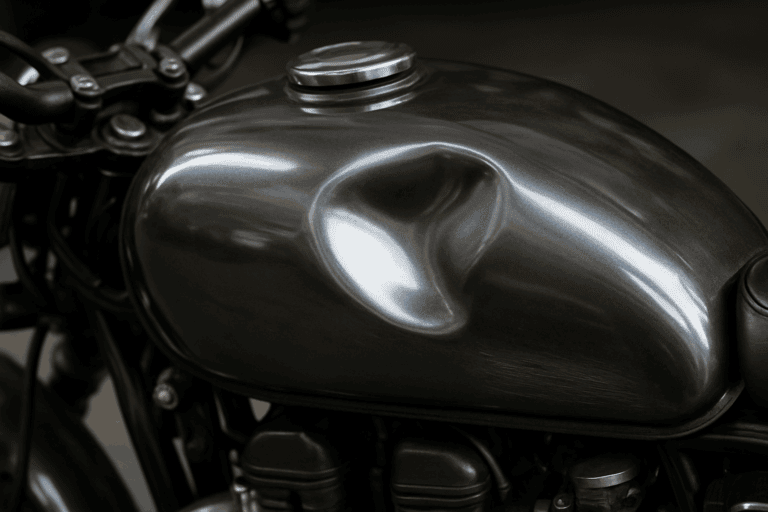

Paintless Dent Repair (PDR)

While paintless dent repair (PDR) has been around for some time, recent technological advancements have enhanced its efficiency and environmental sustainability, making it a leading choice in contemporary auto body repair. Technicians utilize specialized instruments to carefully push out dents from vehicle panels without affecting the original paintwork.

Improvements in PDR lighting, tool development, and training methods have broadened the range of issues that can be addressed with this technique. Now, even more significant dents and damage from hail can frequently be repaired without the need for a repaint.

For vehicle owners, this development translates to reduced repair costs, quicker service times, and the ability to retain the original factory finish — all vital for sustaining resale value.

Computerized Frame Straightening

After a major accident, preserving a vehicle’s structural integrity is crucial. While frame repairs once depended on manual adjustments prone to error, modern shops now use computerized measurement systems that match the vehicle’s structure to factory specifications with millimeter precision.

These systems not only restore frames to their original condition but also generate digital reports, helping technicians and insurers document repairs with greater transparency and safety assurance.

This focus on precision represents a substantial advancement in improving the safety outcomes of repaired vehicles.

Advanced Materials and Repair Techniques

Cutting-Edge Materials in Contemporary Automobiles

Modern automobiles incorporate advanced materials such as high-strength steel, aluminum, carbon fiber, and composites to improve fuel economy and enhance crash protection. Although these materials are beneficial, they necessitate unique repair techniques.

Specialized Repair Tools

Repairs involving aluminum require specific workspaces and non-ferrous welding equipment, whereas carbon fiber necessitates particular adhesives and curing processes. This ensures that each material is treated appropriately to maintain safety and accuracy.

Innovative Repair Methods

Techniques like laser welding, adhesive bonding, and rivet bonding have taken the place of many conventional practices. These methods provide robust, manufacturer-approved repairs that enhance both durability and safety.

3D Printing for Replacement Parts

The incorporation of 3D printing technology is revolutionizing the auto restoration industry. In instances where parts are hard to find or are out of production, repair shops can utilize 3D printing to create exact replicas as needed.

Whether it’s minor plastic clips or specialized trim elements, 3D printing helps customers save both time and costs. As this technology continues to evolve, it is anticipated that more repair shops will embrace 3D printing for intricate components, minimizing delays and providing access to rare parts.

This advancement not only enhances operational efficiency but also lessens reliance on global supply chains, which can lead to prolonged waiting times for specific components.

Robotics and Automation in Collision Repair

- Precision Coating: Robotic technology ensures an even application of paint with exceptional precision, minimizing waste and achieving perfect finishes.

- Automated Surface Preparation: Machinery performs time-consuming sanding and polishing tasks swiftly while maintaining uniform quality.

- Enhanced Productivity: Automation accelerates repair processes, enabling shops to accommodate a greater number of clients efficiently.

- Labor Assistance: By assuming monotonous duties, automation aids shops in addressing workforce shortages.

This means that customers can expect quicker repair durations and more reliable outcomes.

Eco-Friendly Innovations in Collision Repair

The emphasis on sustainability is increasingly important in the field of auto restoration. Innovative technologies allow repair shops to lessen their impact on the environment by implementing:

- Water-based paints that release fewer toxic substances.

- Energy-saving curing systems that minimize electricity consumption.

- Initiatives for recycling outdated components and materials.

By embracing environmentally friendly practices, collision repair businesses not only adhere to environmental laws but also attract customers who prioritize sustainability.

The Road Ahead: Future of Collision Repair

As cars become more automated and powered by electricity, the collision repair industry is set to change significantly. For example, electric vehicles (EVs) necessitate expert knowledge for safe battery management. Repair shops will need to respond to these new demands by training their staff and acquiring appropriate tools.

In the future, we can anticipate a deeper integration of artificial intelligence (AI), augmented reality (AR), and virtual reality (VR) within the auto repair process. AR applications may enable technicians to project digital repair instructions directly onto the cars, while AI could enhance efficiency in sourcing parts and managing workflows.

The collision repair sector stands at the crossroads of skilled craftsmanship and cutting-edge technology. Tasks that once depended mainly on manual labor now require a blend of technical know-how, digital skills, and an ongoing willingness to embrace new innovations.

The landscape of collision repair is undergoing a significant change due to advancements such as digital imaging, 3D printing. These technologies enhance the speed, safety, and accuracy of repairs for car owners. For repair shops, embracing these innovations is crucial to maintain competitiveness in an era where vehicles are increasingly intelligent and intricate.